Thermal Transfer Labels

Used for industrial printers

Print and apply applications

Used for desktop and industrial printers

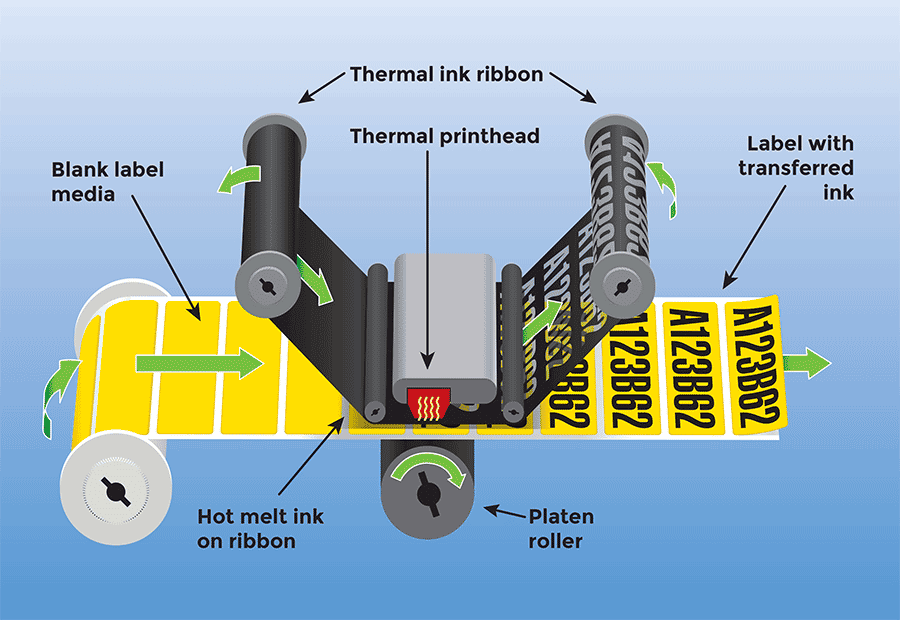

Thermal transfer labels are versatile and widely used for applications such as product labeling, asset tracking, and compliance labeling. They are designed for use with thermal transfer printers, which utilize a ribbon to transfer ink onto the label surface, ensuring durability and resistance to harsh environments.

Key Considerations:

- Label Material: Thermal transfer labels are available in various materials, including paper, polyester, or polypropylene. Choose the material that suits your specific requirements for durability, moisture or chemical resistance, and longevity.

- Adhesive: Select the appropriate adhesive based on the surface and desired adhesion strength. Thermal transfer labels offer options for permanent, removable, or repositionable adhesives.

- Label Size and Shape: Choose the size and shape that fits your application. Standard sizes are available, or you can opt for custom-cut labels to meet your specific needs.

- Ribbon Compatibility: Ensure compatibility between the labels and the thermal transfer ribbon used in your printer. Different ribbons may have varying requirements for label material and size.

- Print Quality: Thermal transfer labels offer high print quality, allowing for detailed and crisp images, text, and barcodes. Consider the resolution and clarity required for your labeling purposes.

- Durability: Thermal transfer labels provide excellent durability, resisting fading, smudging, and scratches. They are suitable for long-term labeling needs and harsh environments.

- Quantity: Determine the quantity of labels needed and select the appropriate roll size to meet your volume requirements.

Ensure compatibility between the labels and your thermal transfer printer for optimal performance.