Direct Thermal Labels

Used for desktop printers

Used for Industrial printers

Used for desktop and industrial printers

1″ Core: Used for desktop printers

3″ Core: Used for industrial printers

Fanfold: Used for desktop and industrial printers

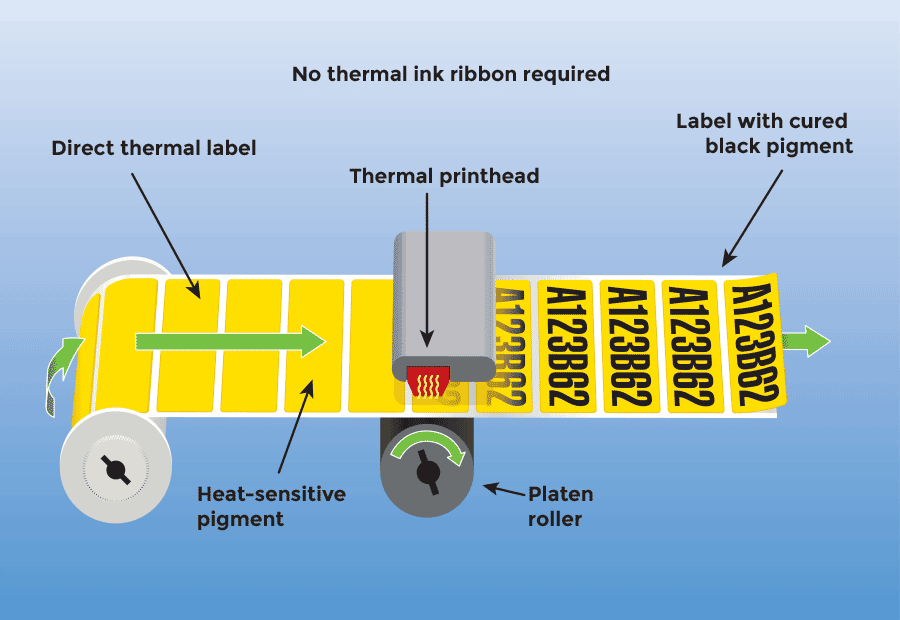

Direct thermal labels are ideal for various applications, including shipping labels, barcode labels, name tags, and receipts. These labels are specifically designed for use with direct thermal printers, which utilize heat to create an image on the label surface without requiring ink or toner.

Key Considerations:

- Label Material: Direct thermal labels are available in coated paper or synthetic materials like polypropylene or polyester. Choose the material based on your requirements for durability, moisture or chemical resistance, and label longevity.

- Adhesive: Labels come with permanent, removable, or repositionable adhesives. Select the appropriate adhesive based on the surface and desired adhesion strength.

- Label Size and Shape: Choose the size and shape that suits your application. Standard sizes include 2″ x 1″, 4″ x 6″, or custom-cut options.

- Core Size: Consider the core size of the label roll to ensure compatibility with your printer. Common core sizes are 1″ or 3″.

- Print Density: Determine the print density based on the level of detail required. Higher print densities offer more detail but may impact printhead wear.

- Durability: Assess the durability requirements of your labels. Direct thermal labels are sensitive to heat, light, and contact. For harsh conditions or long-term readability, consider thermal transfer labels.

- Quantity: Determine the quantity needed. Direct thermal labels are typically available in rolls, with varying label quantities per roll.

Ensure compatibility with your specific direct thermal printer, as printer requirements may vary.

Choose the right direct thermal labels for your labeling needs by considering these factors.